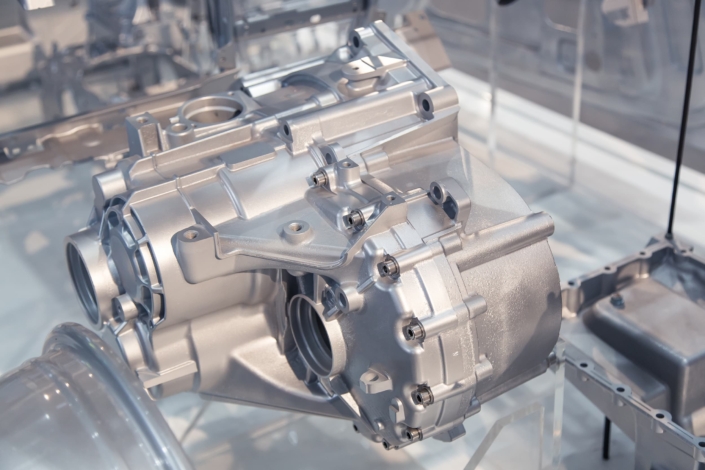

Die-Casting

Die-casting is a sophisticated process that plays a crucial role in various industries, including automotive and electronics, by bringing intricate metal components to life.

At the heart of successful die casting lies the die temperature, which significantly influences the dissipation of heat from the molten material, the proper filling of the mold, and the accurate setting of the cast part. Failure to maintain the die at the optimum temperature can lead to defects in the casting process.

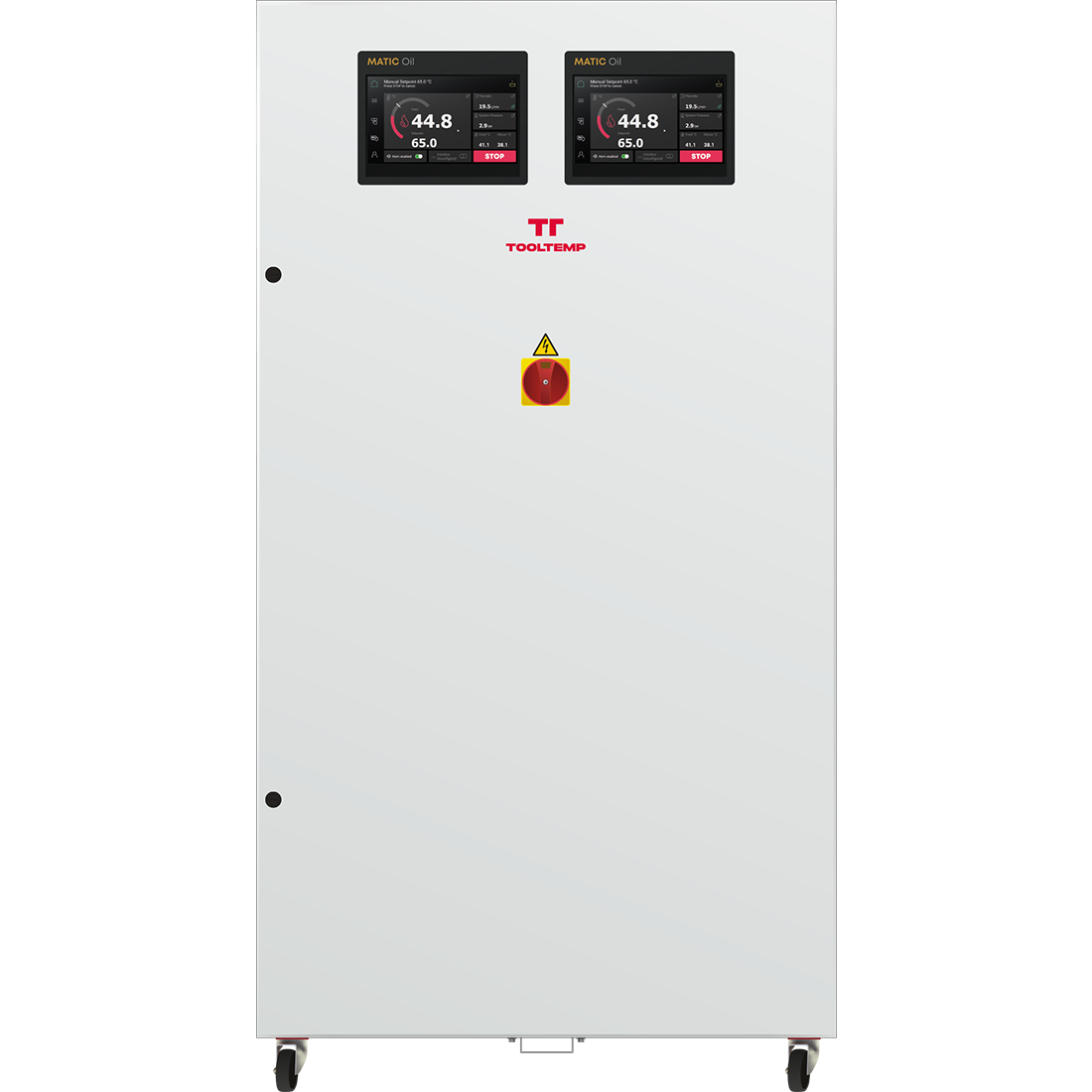

This challenge is effectively addressed by utilizing our advanced temperature control units, which are designed to ensure precise temperature control throughout every stage of die casting. Our commitment to supporting production processes with tailored temperature control solutions is unwavering. We take pride in offering a comprehensive range of Tool-Temp temperature control units that cater to a wide array of die-casting methods, ensuring that our customers have access to the most suitable equipment for their specific needs.

Our products are engineered to deliver precise and consistent performance, contributing to the efficient operation of die-casting processes. Moreover, we are dedicated to ensuring optimal customer satisfaction by offering quick repair services, a comprehensive inventory of spare parts, and personalized technical advice and troubleshooting assistance.

We are committed to being a valuable partner regardless of location, production requirements, or language barriers, and our support is available whenever and wherever our customers need us.