Rubber – Shoe

Rubber plays a crucial role in both the global economy and the daily lives of people around the world. As society progresses, the demand for rubber-based products continues to rise steadily. It’s important to note that both natural and synthetic rubbers undergo distinct production processes. Some of the most commonly used techniques for natural rubber processing include extrusion, immersion in latex, molding, and calendering.

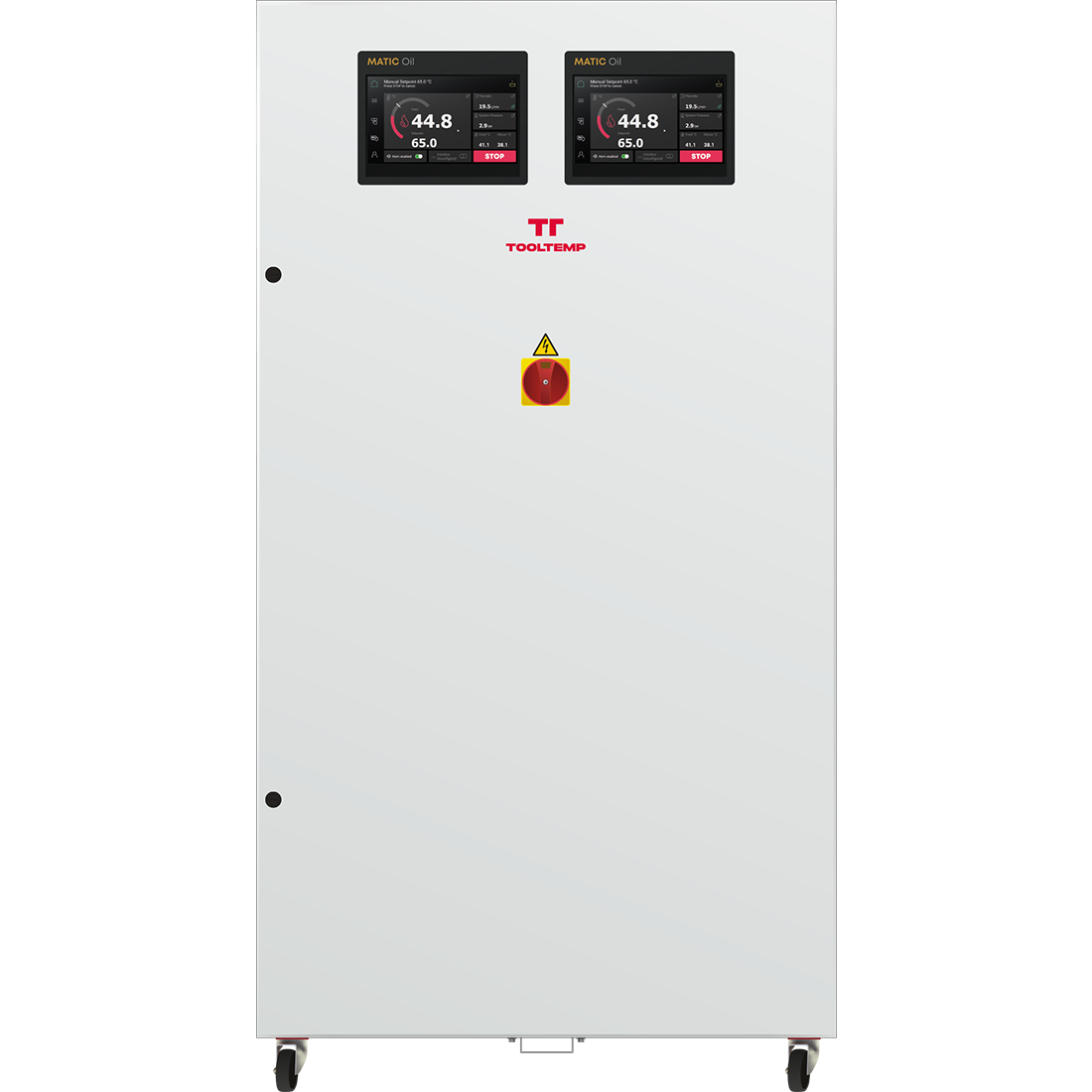

At HTL TECH, we pride ourselves in offering a comprehensive range of temperature control systems that are designed to meet diverse temperature ranges, volume flows, and system integration requirements, tailored to various processing methods.

We understand the significance of maintaining reliable raw material quality, ensuring precise weight proportions of different ingredients, overseeing controlled mixing procedures, and optimizing forming processes when it comes to producing components made of elastomer materials. Our commitment is to address all your temperature control needs, whether it be through providing standalone solutions or fully integrating our systems with your existing processes.

Furthermore, while the demand for rubber continues to soar, it is crucial to recognize that this growth may outpace the supply of rubber trees. This discrepancy is attributable to factors such as limited land availability, evolving climate conditions, and various challenges in resource management. At HTL TECH, we offer sustainable recycling solutions as a means of effectively addressing this challenge. By repurposing and reusing rubber materials, we can help mitigate the impact of resource scarcity while satisfying the escalating demand for rubber.

In addition, we understand the importance of providing rapid responses for tailored customer solutions as an integral part of our service. Our aim is to ensure optimal solutions, allowing you to concentrate wholeheartedly on your production processes.