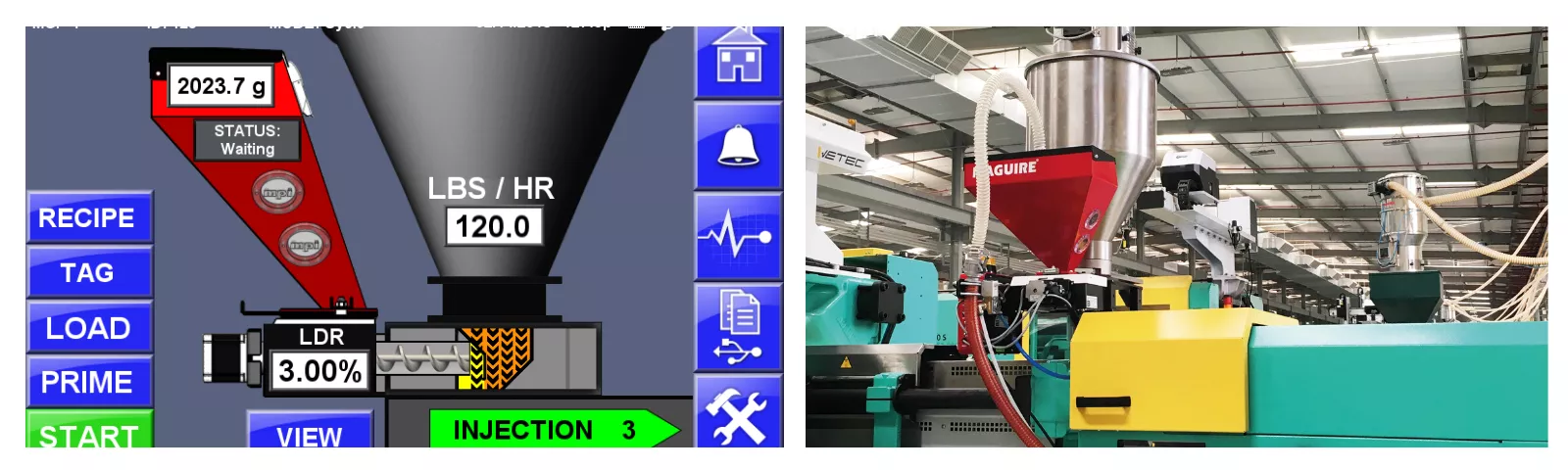

MGF Gravimetric Feeders

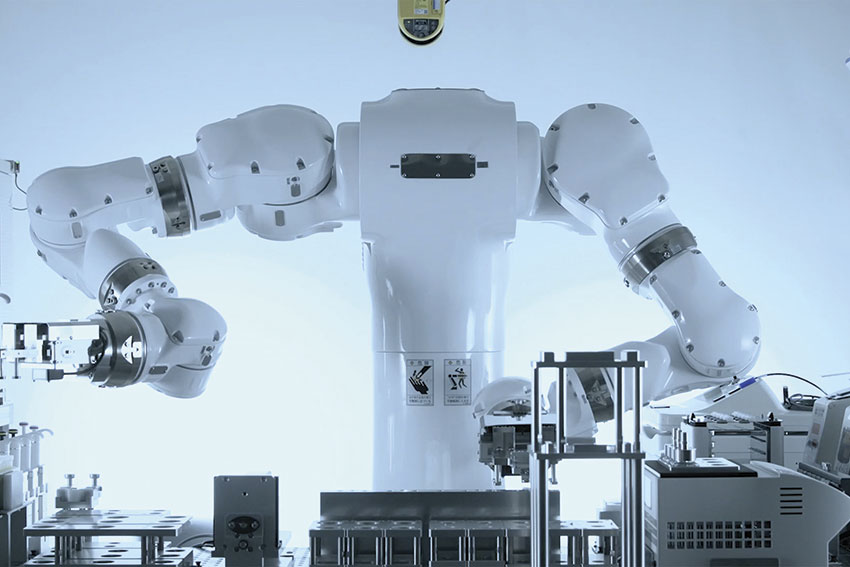

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy.

- Unique twin load cell technology

- Dosing accuracy ± 0.2% on 1% setting

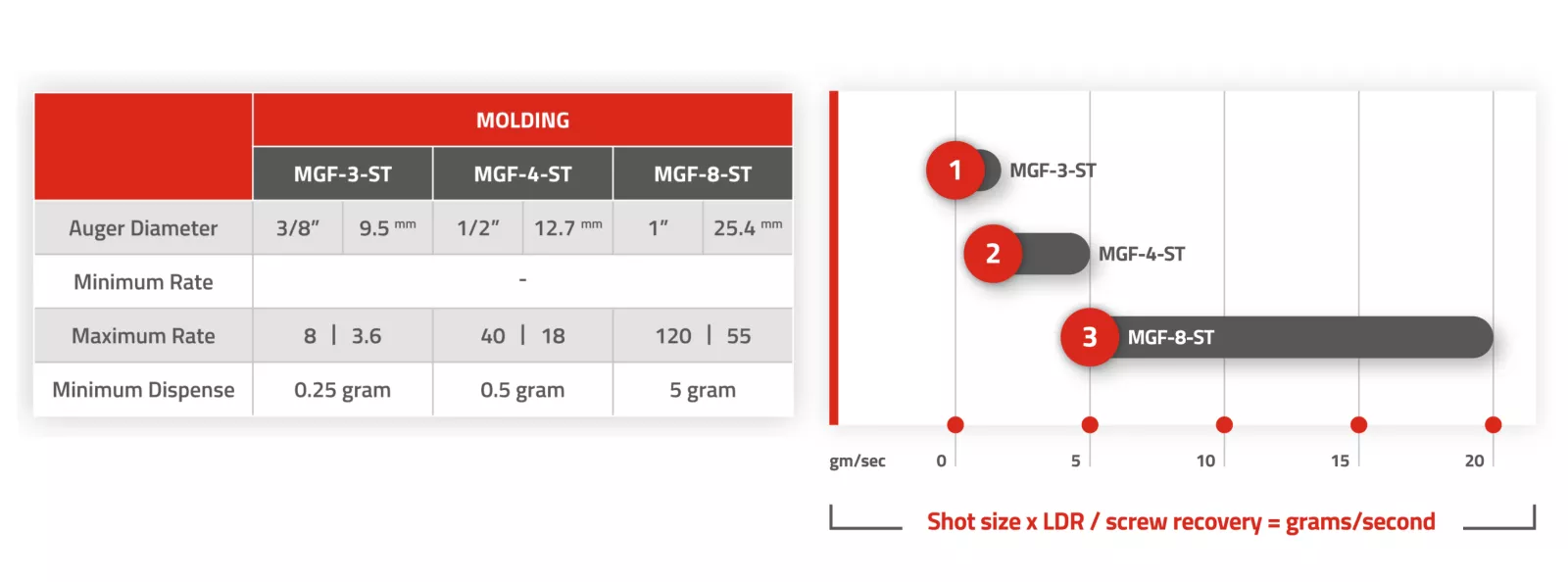

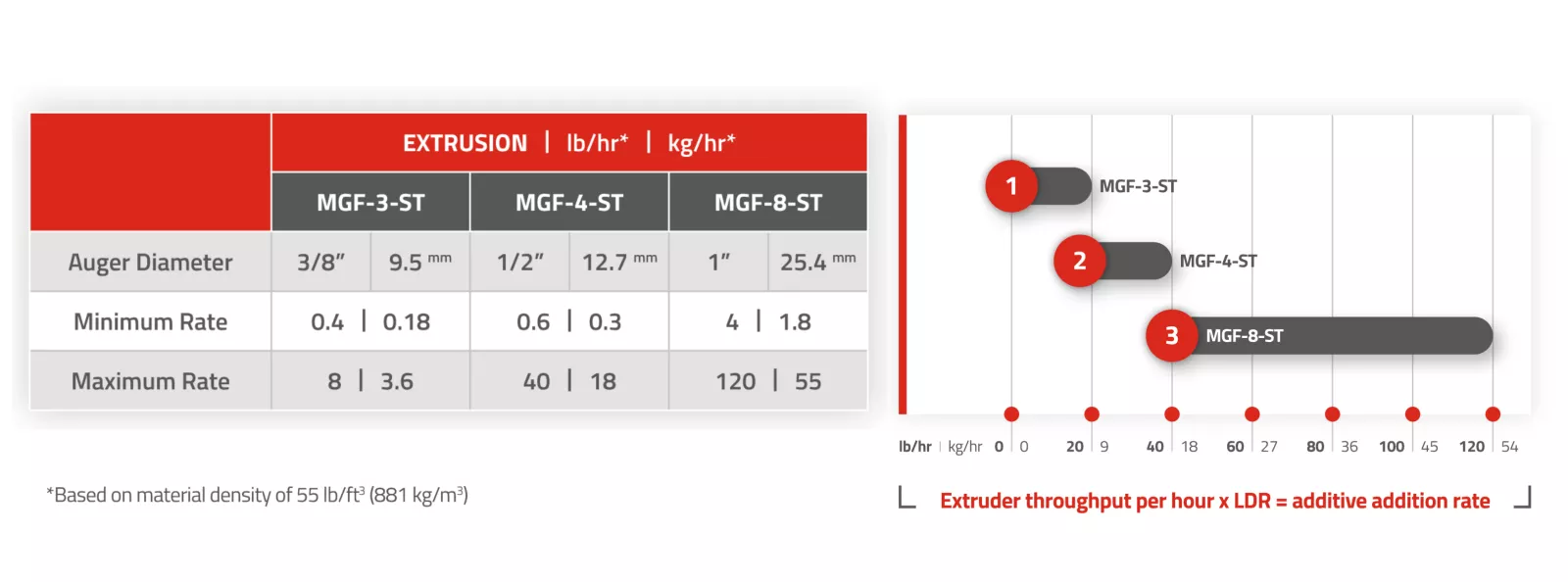

- Feeder ideal for all molding and extrusion processes

Gravimetric Accuracy

Return on Investment

- MGF software and hardware reduce waste of colorants and additives drastically.

- Maguire Gravimetric Feeders eliminate manual handling and mixing and reduce operation costs.

- Save typically 30% on masterbatch costs compared to manual or volumetric dosing.

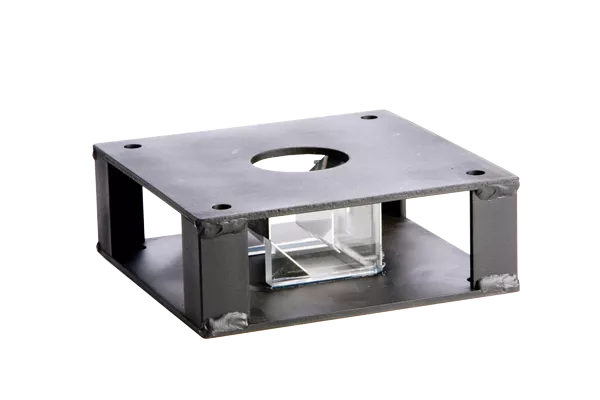

Twin Load Cells

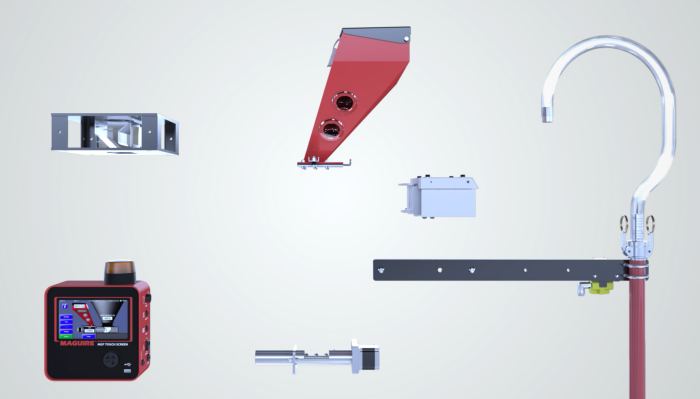

- Lightweight aluminum hopper mounted on 2 load cells which measure the weight of the hopper and the material ONLY.

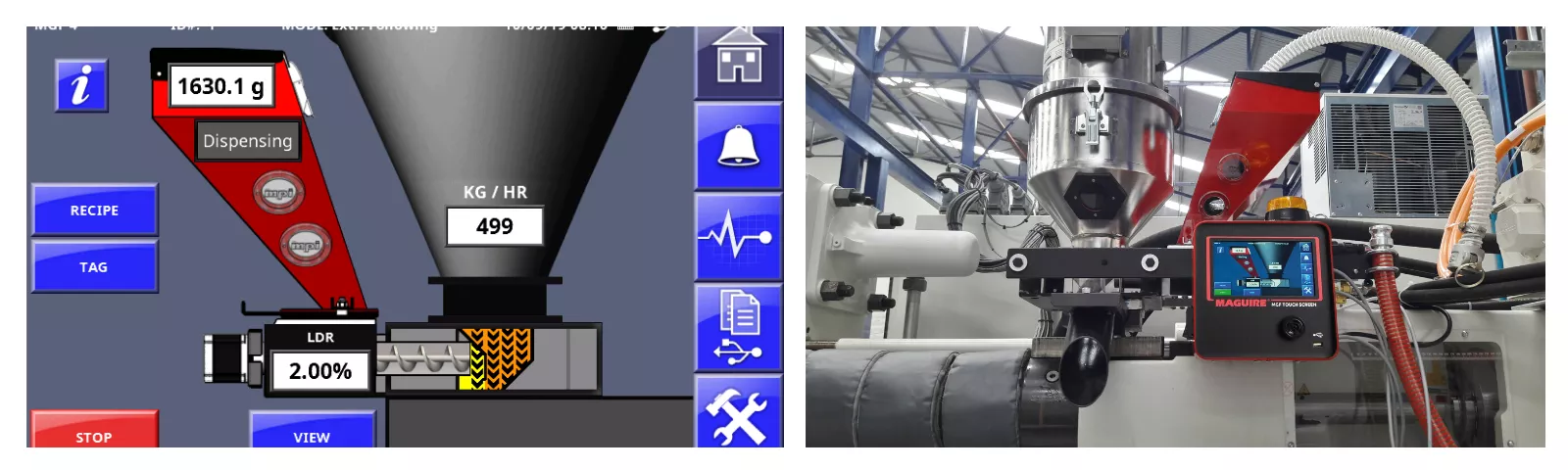

- Continuously monitors the loss-in-weight as material is dosed and automatically adjusts flow rate.

- Measuring only the hopper and masterbatch allows for finer resolution load cells versus weighing complete feeder assembly and motor. This achieves maximum accuracy and control.

Accuracy of ± 0.2%

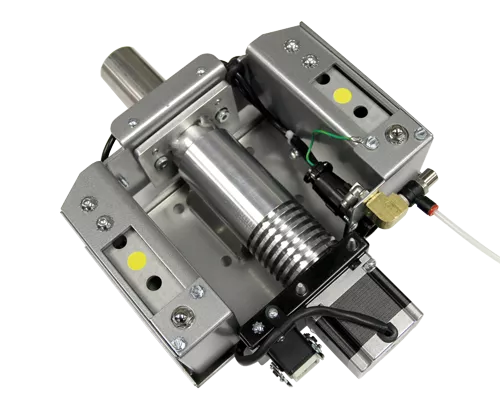

- Automatic, continuous updates to flow rate calibration during production process.

- Stepper motor provides high resolution control to dose masterbatch accurately to ± 0.2%.

- Choice of dosing screws combined with software control provide industry-leading accuracy.

PRIME Calibration (patented)

- Fast-track calibration on startup. Fully automatic and ready within seconds.

- Primes screw and barrel with material, ready to start production.

- Quicker startups and reduced scrap rates.

100% Injection Coloring (patent pending)

- For critical additives, masterbatches and tints.

- All material in injection molding machine barrel is now colored and gaps are eliminated. No scrap.

- Ideal for fast cycling / small shot weight applications.

Build your Knowledge | How to Dose Consistently in just 5 Minutes:

Continuous Accuracy

Continuous Accuracy